Izumi Hydraulic Crimpers & Dies: Keep the Door Rolling

A garage door manufacturing company contacted us for a crimping solution. They provide and install a range of roller doors for residential houses and sheds.

They wanted to be able to cut and crimp the wires that raised and lowered the roller doors in-house, previously they had purchased the wire assemblies complete. Purchasing the assemblies complete meant replacement wires for their sectional or standard roller doors, custom height doors or emergency service needed to be ordered, which could add lengthy delays for their customer.

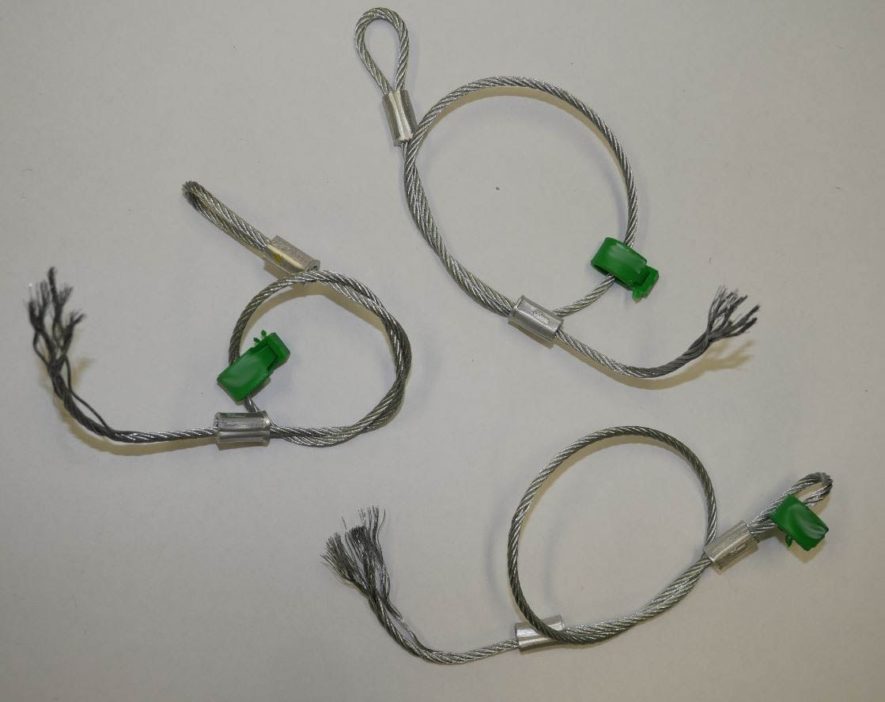

The customer had organised sourced some sample aluminium crimp ferrules or sleeves and galvanised steel wire but had no tooling and had not done any testing. As the doors are supported over people they had to ensure their ferrules and wire assemblies were quality and able to be continuously operated well into the future. Two different crimps were required: one was single ferrule crimped with single wire; the second was single ferrule with loop end so two wires.

The previous manufacturer of the assemblies was crimping the units in an unconventional manner which was not hex (as per standard power cable lug crimping) or round swaged (common for small wires and cables. SF carried out some testing of some initial sample assemblies using some existing common hex cable dies, these passed our first manual attempts at pulling them apart.

The equipment used to make up the test samples:

- Izumi battery hydraulic crimper 12 tonne (Model: REC-6431(BB))

- SF crimp dies 12 tonne various hex sizes (Model: 12T**.*CU)

The next step in the testing process was official testing. To perform the testing and record the results accurately several sample units had to be made up. By using the following SF in-house equipment:

- Durapac manual P-Series hand pump (Model: P-2200A, 700bar)

- Durapac calibrated test gauge (Model: PG-100)

- Durapac tested hydraulic hose with couplings and dust caps (HPS-0603DR)

- Durapac pull cylinder (Model: RAP-106, 10 ton)

- Dillon calibrated Electronic Dynamometer EDxtreme with Wireless Display (Model: EDX-5T with remote communicator)

- Pull test frame (engineer certified)

- Chain rated and inspected

- Shackles rated and inspected

Industry safety standards, criteria and safety factors were applied to the average result of the test values, which exceeded expectations and requirements.

As standard hex cable dies are designed for soft ferrous cables and lugs (aluminium and copper) these were suitable for the application. For stainless steel wires/cables and ferrules/sleeves we have higher grade hardened dies manufactured.

A test report was issued. The customer was advised about holding onto the test samples and ensuring quality checking of materials and performing random batch testing.

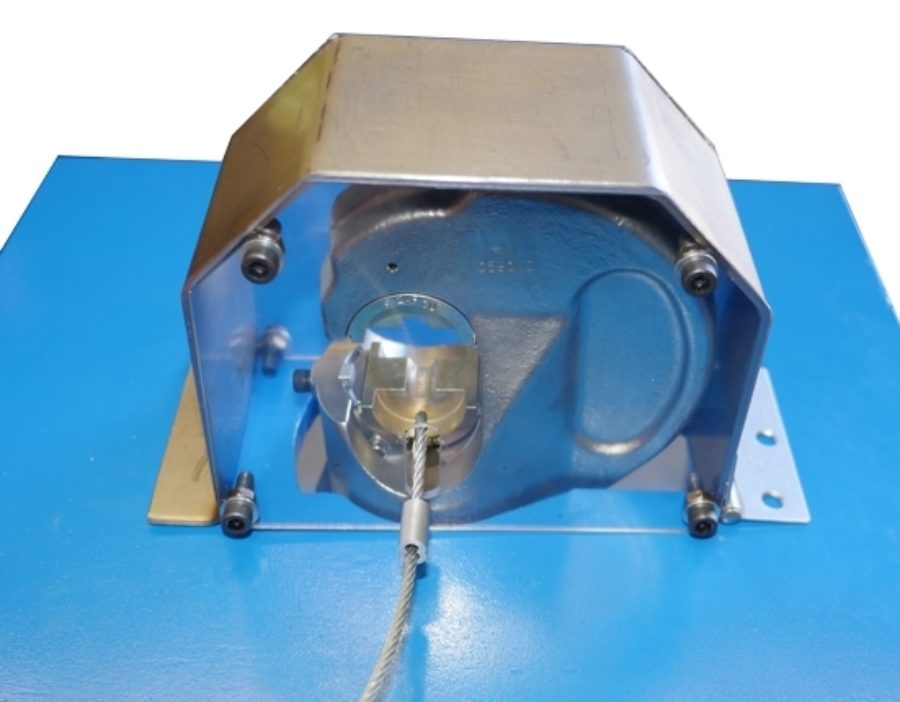

As testing was complete, we were now able to provide the tooling. Our technical sales representative wanted to provide the best and safest solution for the customer. The customer wanted to perform the crimping in the warehouse so we offered to build a custom height stand with remote hydraulic crimper head mounted atop the stand. As this was new equipment for this customer and workers safety precautions had to put into place. A clear Perspex safety guard was suggested with a small entry hole so that the operator could only insert the wire and ferrule to be crimped, which meant avoiding accidental crimping of their fingers. As a hydraulic pump is required to operate the remote crimping head, an electric pump would be placed on a shelf of the stand. Instead of using a standard hand controller a foot switch was offered for the pump which allows the operator to keep both hands free for positioning of material to be crimped.

Our offer for the final set of equipment which the customer ordered was:

- SF custom made crimping stand with finger guarding for crimp head

- Izumi remote hydraulic crimp head 12 tonne, high repetition (Model: EP-410HF)

- Durapac hydraulic high pressure hose 700bar with couplings and dust caps (Model: HPS-0603DR)

- Riken electric hydraulic pump 700 bar (Model: SMP-40AR-67B)

- Riken foot switch for SMP-40AR-67B pump (Model: SF1)

At SF we make and provide custom solutions to suit your crimping, pressing or cutting problems or processes. Either on-site/mobile or high factory production.