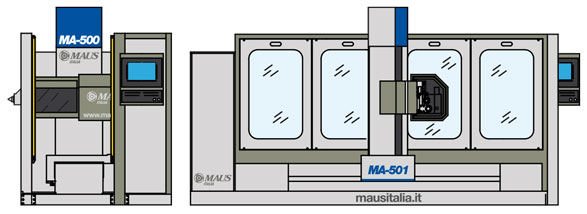

Maus MA-500 Single Axis CNC Working Centre for Rolling and Facing

Fixed-base single-axis CNC work centre for rolling and end facing of tube bundle tubes

Fixed-based single-axis CNC work centre for serial production rolling and end facing of tube bundle tubes.

- The MA-500 is the most innovative and efficient of Maus Italia's products for the automation of serial production assembly work cycles for small heat exchangers.

- Hi-tech

- Maximum productivity

- 600 tubes/hour (1 cycle every 6 seconds)

- Lasting reliability

Enter the Industry 4.0 with MA-500

The CNC/PLC machine manufactured by Maus Italia perfectly follows the requirement of the "Internet of things" being equipped of systems that allows to obtain data and statistics indispensable for handling the internal process and to be able to take strategic decision for the company development.

CNC-Controlled Automatic Tooling

Automatic Rolling Expansion

- The automated rolling cycle reaches levels of productivity and quality that are incomparable with those attained by traditional systems.

- Total control over both the torque and the size of the tube allows you to highlight and configure the phases of the process during rolling expansions, thus optimizing working times.

- A second advantage of this revolutionary technology is the considerable reduction in the tool wear.

- Complete and detailed reports and storage of data in real time.

Automatic End Facing

- The completely automatic system can be used for removal of excess material as well as welding preparation.

- The automatic end facing system includes compensation for the deformation of the tube sheet, optimizing the process from both a qualitative and a productive point of view.

The Numbers that Count

- Diameter of tube sheet max. 1000 mm (40") - Other sizes available on request

- Thickness of tube sheet max. 200 mm (8")

Diameter of Tubes:

- First line of mandrels: between 6 and 16 mm ( between 1/4" and 5/8" ) – light version

- Second line of mandrels: between 9,5 and 51 mm ( between 3/8" and 2" ) – heavy version

The MA-500 CNC work centre allows the single axis execution of rolling and end facing of the tube bundle tubes: completely automated processes at extremely low cost and with a significant reduction in production times.

- The MA-500 work centre is the most technologically advanced product on the market: it is the preferred choice for those seeking quality and performance.

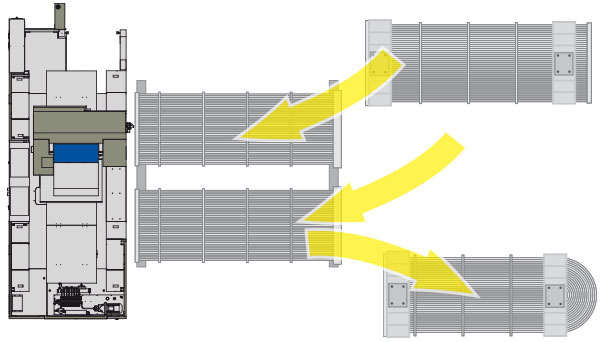

Work Layouts

The automation of the processes in the assembly of heat exchangers permits different configurations according to the workshop, significantly increasing productivity.

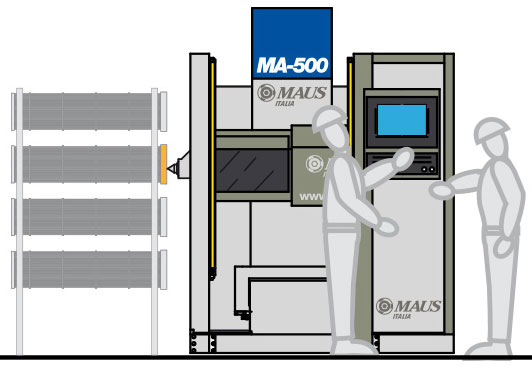

Fix Positioning Automatic Process

Layout of fix positioning in which the heat exchanger of medium dimension are moved in front of the machine that will ultimate the zero piece setting in just few minutes thanks to the hydraulic base and the centering device FOCS.

Automatic Operation with Multiple Tube Bundle Loader

Work configuration with a multiple tube bundle loader for optimising serial production of small tube bundle heat exchangers.

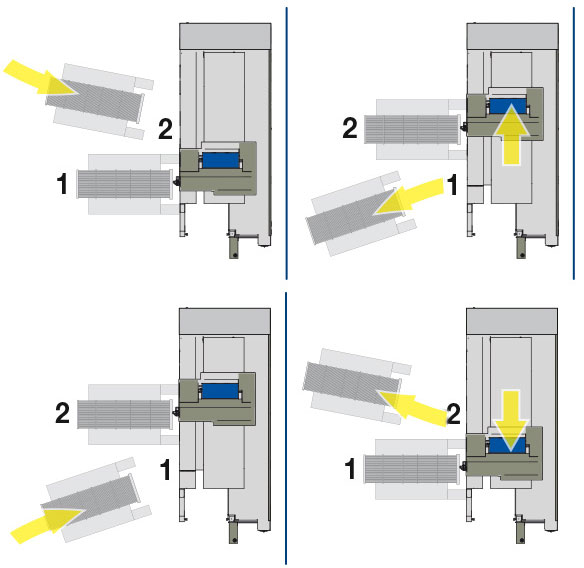

Pendulum Machining with Trolleys

Pendulum machining configuration with trolleys for small heat exchangers where continuous alternation of position in front of the machine eliminates load/unload dead times, significantly increasing production.

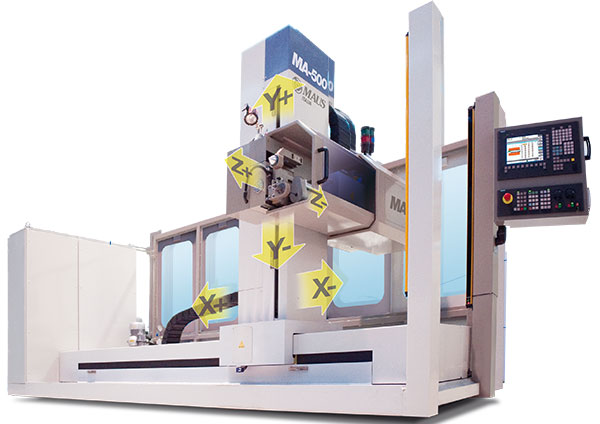

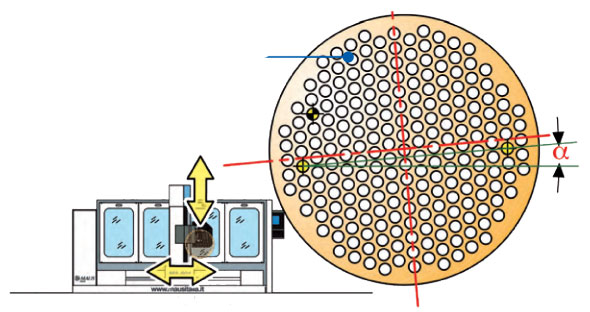

Revolutionary Operation on 3 Axes

The remarkable uniqueness of the MA-500 is in its capacity to work simultaneously on 3 axes: horizontal, vertical and transverse.

- X axis carriage: The MA-500 moves laterally along a carriage support column for horizontal positioning in front of the heat exchanger.

- Y axis carriage: The MA-500 is equipped with a carriage for the vertical stroke and to support the Z axis with the operating axis for the vertical positioning of the machining head.

- Z axis carriage: Carriage for the transverse stroke to approach the tube sheet.

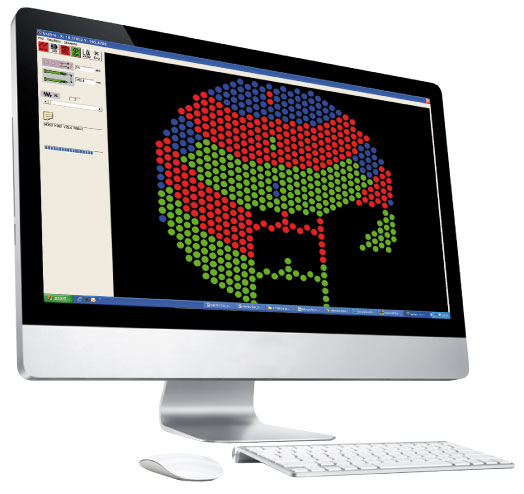

MAUSCAM Interface Software for CAD Design of CNC Programming

Using MAUSCAM software, you can download the X-Y coordinates of the centre of the tube sheet holes on to the MA-500 and select the optimal machining course as required.

The Main Structure of the MA-500

- The column is an extremely robust and compact electro welded normalized steel structure located on the X axis carriage.

- The tool head can be variously fitted with semi-automatic tools for rolling and end facing.

- The electrical cabinet on board the machine is climate-controlled for automatic control of its internal temperature.

- The control console is positioned so as to ensure maximum visibility of the working zone. The CNC display guarantees maximum operational simplicity.

- The remote control allows the operator to manually control the machine's main movements by being close to the operative area in total safety.

- The safety system is supplemented by a set of fixed and mobile photo electric safety barriers. The sliding door with electromechanical interlock completes the protection of the mandrel rotation area.

- An automatic internal lubrication system for the tools, equipped with an appropriately programmed minimum level sensor, automatically manages the lubrication of the tube expander.

Unique FOCS2 Centering System

The unique FOCS2 centering system is a self-learning electro pneumatic device for automatic tubes centering and correction.

- This device is controlled by software exclusively designed by Maus Italia.

- Rapid detection of zero setting, calculation and storage of the grid location of the holes in the tube sheet.

Applied Technologies

Zero Setting

Collimation by the CNC program of the matrix of the hole centers of the tube sheet to the machine zero. A semi-automatic procedure combined with the FOCS2 self-learning centering laser feeler allows you to calculate and store the actual position and rotation of the tube sheet in relation to the machine.

Free Tubes

The rolling of a tube which is simply inserted into the tube sheet but not locked and therefore free to move longitudinally was one of the first issues to be solved successfully by the Maus Italia MA series.

- The MA-500 can lock and roll a free tube, at the desired protrusion, totally autonomously and automatically.

- This technology can be used in the orbital welding preparation.

Parallel Roll

RP technology allows elongations and related residual stresses in the tube after rolling to be reduced to a minimum, in order to obtain a homogeneous tube-tube sheet contact along the whole length of the expansion.

- This involves the use of mandrels with the axis of the housing seat of the rolls parallel to the axis of the cage: this results in a more cylindrical tube, a reduction in the elongation of the tube, the independence of the feed speed of the mandrel from the speed of rotation of the expander and a reduction in the wear of the tools.

Automatic Compensation for Depth of Expansion

Automatic zero setting system for Z axis, the position reference is the outer edge of the tube sheet for each individual tube, regardless of the deformation of the tube sheet itself.

Mandrel Feed Digital Control

The digital control allows you to check in real time the actual size of the tube expansion.

- This technology allows you to record the value of each expansion carried out.

Continuous Speed Variation

The rotation speed of the expander mandrel varies continuously as a function of the torque moment by moment: this results in an optimization of the expansion cycle, a reduction in the wear of the tools and a greater speed of execution.

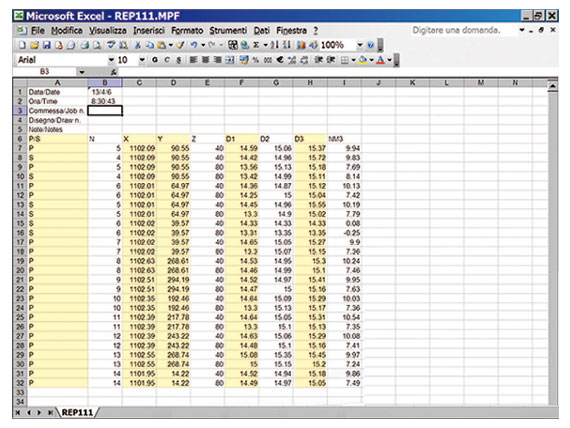

Reporting of Automatic Rolling Expansions

The continual and growing demand for documentation suitable for certifying the overall quality of a company is met by complete and detailed data storage.

- The MA-500's automatic rolling operation with torque control allows you to highlight and configure all the phases of the process which are recorded and monitored on a digital report file, guaranteeing complete traceability of each operation without the possibility of errors.

Click on the link to download more information on the Maus MA-500 Single Axis CNC Working Centre for Rolling and Facing.