alkitronic® EAF-R Battery Torque Wrench/Torque Multiplier

Applications

- These tools are ideally specialised for bolting connections on plate heat exchangers, e.g. in the food and beverage sector, the paper industry and the chemical industry. They save much time when tightening and loosening plate packs where perfect retention and absolute tightness are essential.

- Reliable, low-wear operation due to continuous rotation when bolting with spindles or long threaded bolts.

- Depending on the application, electrical or pneumatic driven torque multipliers: torque up to 4,840 Nm

Advantages

- Load-free operation, with short assembly time.

- Fast gear for turning in and simple, quick switching to power gear.

- SG output can be separated; the respective drive can be used individually as a complete torque multiplier.

- Low weight, ergonomically designed, low noise emissions.

- No noise protection necessary.

alkitronic® Specials

- Targeted types for convenient working in every tightening situation: among other options between radial gearing (R) with high-performance worm drive; tangential gearing (SG) with highly efficient spur gear.

- Long lifetime due to extremely robust motor housing made of cast aluminum or break-proof polymer.

- Supplied in sturdy plastic cases.

- Successfully used worldwide by manufacturers, service companies and end customers for over 35 years.

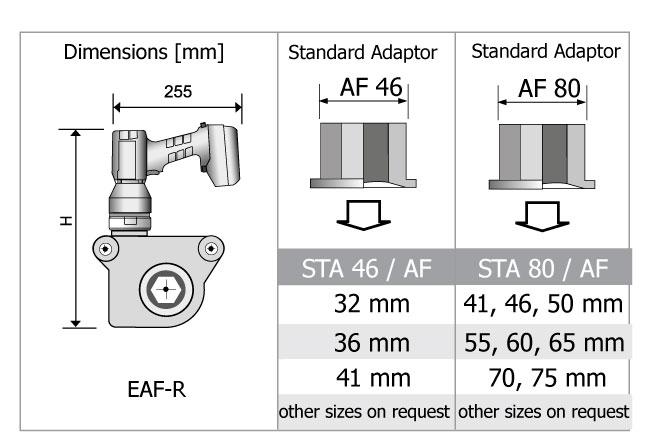

Technical Data Model: alkitronic® EAF-R

| Radial Gearing Models | electric (battery) | |

| Model | EAF-R 46 | EAF-R 80 |

| Torque range 2nd gear (approx.) Nm | 250-730 | 250-730 |

| Torque range 1st gear (approx.) Nm | 750-2500 | 750-2500 |

| Width across flat (AF) mm | 46 | 80 |

| Height (approx.) H mm | 400 | 450 |

| Width (approx.) B/B1 mm | 252/215 | 325/240 |

| Bolt distance (approx.) A1/A2 mm | 112/145 | 156/194 |

| Dimensions (approx.) X/Y mm | 75/75 | 98/98 |

| Dimension (approx.) D mm | 94 | 94 |

| Weight (approx.) kg | 13.5 | 24.5 |

| Idle speed 1st gear (approx.) rpm | 2.5 | 2 |

| Idle speed 2nd gear (approx.) rpm | 8 | 7 |

*) When loosening bolts, a higher torque (up to 20 %) may be necessary (release torque). We will gladly advise you in detail.