OMAC Cable Pulling Machine F260.300.P: Pulling Through

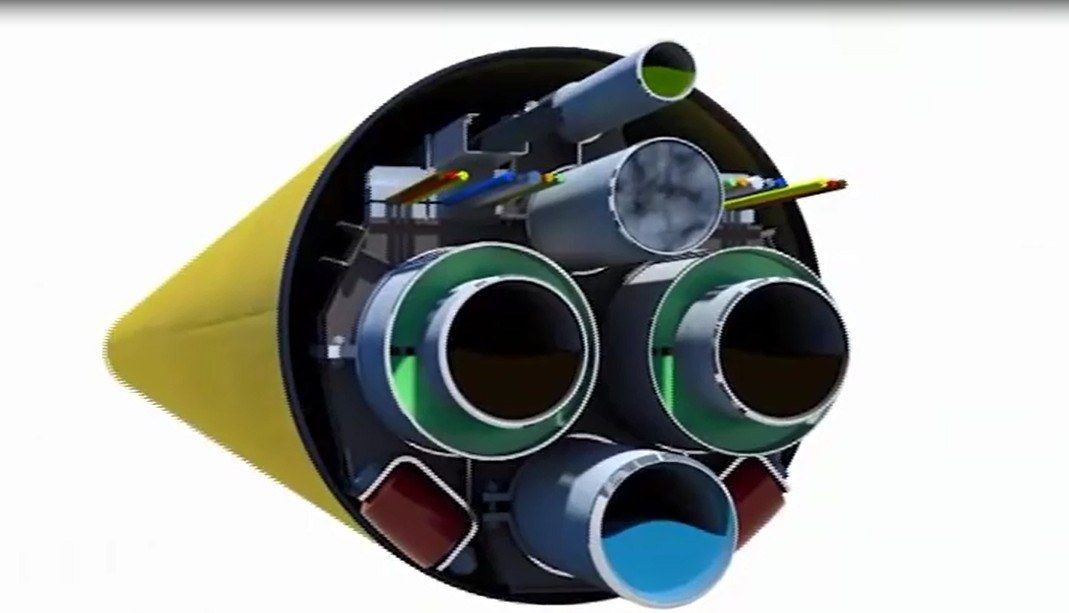

This specialised pulling machine was supplied for Swagelining projects, in this instance it was required for an interconnection project between two countries utilising pipe bundle technology. Pipeline bundles are usually used in subsea applications where one pipe-in-product includes a range of supply items such as electrical, data, water, gas (production lines, gas lifts, water injection and electro-chemical fibres). All included in one outer carrier housing which is laid into a lined pipe for added protection.

The advantage of this specialised pulling machine from OMAC is its capability to pull much longer distances, compared to the standard underground pulling machines of the same pulling capacity. This is due to the special reel winder arm which has the ability to accept reels up to 1.9m in diameter. The rope capacity is up to 1,700m of 32mm Ø pulling rope.

For this specific project pulling through lined pipes the machine was equipped with 1,700m of Dyneema® rope. The benefits of Dyneema® rope is light weight and low wear resistance. The Dyneema® rope also allowed the customer to wrap a high quantity of rope on the arm/reel. This would have not been achievable with galvanised or anti-twist steel rope.

This OMAC Cable Pulling Machine model number F260.300.P features:

- 30 tonnes of pulling force

- Built in data readout and recording facility with USB port to save data

- Safety negative hydraulic brake

- Pull force setting device, maintains a pre-set force even at speed ‘0’ (fit for pipe refurbishing)

- Hydraulic front and back stabilisers

- Reel winder suitable for a 1,900mm Ø reel, with automatic rope winder

- Rope capacity up to 1,700m of 32mm Ø Dyneema pulling rope (less for steel wire rope max 28mm Ø)

This machine was able to save the customer a lot of time and money, being able to pull massive distances meant less pack up and relocation time while also not risking damage to the pipe lining.