Joyce Dayton Jacks: Turning the Tables on Design

Designed for a leading international infrastructure group that finances, develops, builds and maintains complex building programs focused on social and commercial buildings, power and utility systems, and transportation; Joyce Dayton delivered a concept for a unique conference room table that combined both bold and functional handcrafted elements. Inspired by the customer’s ingenious concept, Joyce engineers offered a creative, mechanically sound solution. The resulting lifting system was a perfect fit in both form and function.

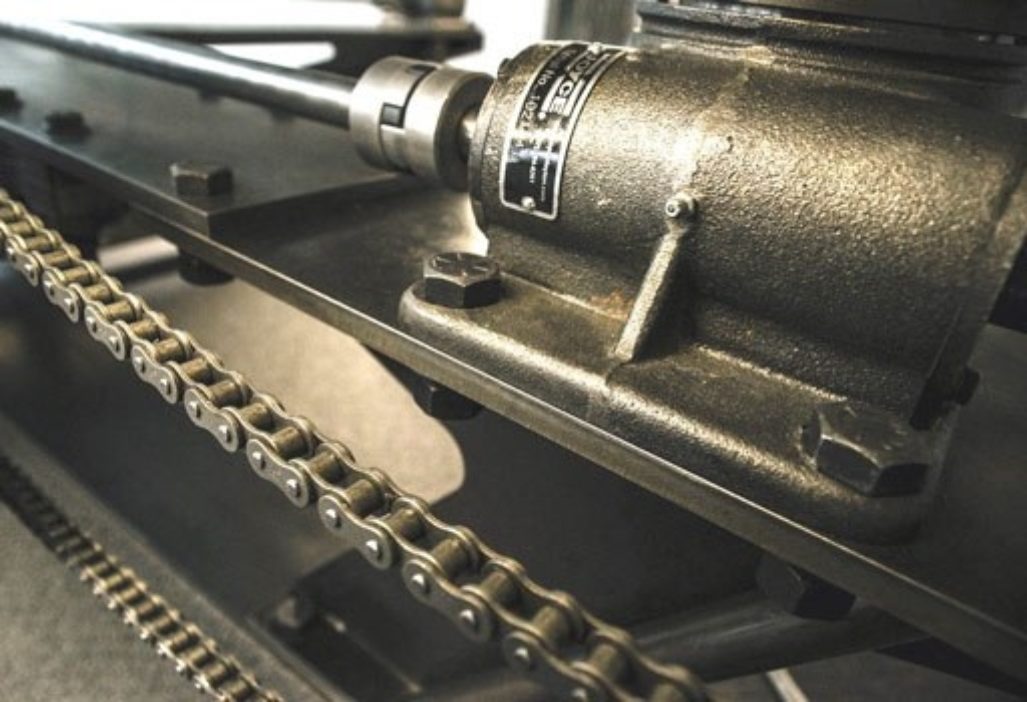

Four ten-ton screw jacks were joined with shafting to a central miter gear box to provide support for the lift table system. The drive component included a chain drive that connected the ship’s wheel to a sprocket on a drive shaft. All jacks lift in unison when the ship’s wheel is rotated.

Translating Worm Gear screw jacks with self-locking screws lift and lower the table. The four-way central miter gear box is connected to the lifting jacks with shafting. It has a hand crafted wood and glass table top, which spans ten feet, rests at four points on the load pads of jack lifting screws. A chain drive connects the lifting system to the ship’s wheel for operation. Unpainted jacks with exposed lifting screws lend an industrial appearance. Users observe “art in motion” through the glass table top.

Joyce engineers, mindful of critical details, developed a complete lift system which included a four-way miter box, shafting, couplings and shaft support bearings. Key to the system’s success was the need to move all four jacks simultaneously and then hold position.

Joyce engineers took the guess work out of the design by laying out a lifting system and recommending the correct combination of self-locking jacks with either right-hand or left-hand gear sets. Compatible system components like the four-way miter box, shafting, and couplings were also recommended.