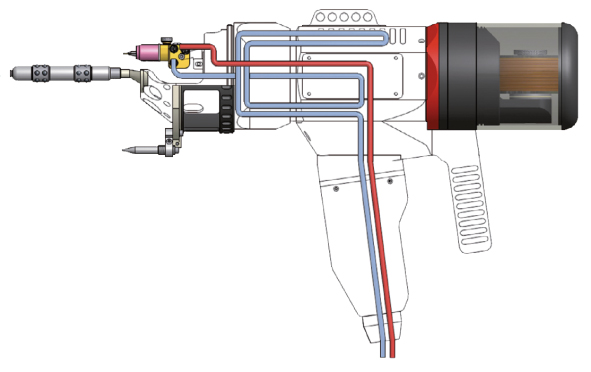

Maus Giotto Standard Orbital Head for Tube to Tube Sheet TIG Welding

Giotto - Orbital heads for tube to tube sheet TIG welding for the manufacture of tube bundle heat exchangers.

- Maus Italia presents its new range of Giotto series orbital heads for tube to tubesheet TIG welding.

- Following thousands hours of R&D, tests and prototyping, the result is an outstanding and unprecedented orbital welding head that is a masterpiece developed, manufactured and assembled in Italy, with the extreme precision and quality you would expect from Maus Italia.

- The series offers a range models for orbital heads which come with a generator of the latest technology and dedicated software.

Features

- Unique product of its kind. The new orbital TIG torch has been designed and manufactured entirely by Maus Italia.

- Filler wire driving system. The constant flow and rotation of the reel on the orbital axis increases the accuracy and quality of the weld.

- Single key settings. Exclusive capability to adjust the geometry of the weld with the single supplied key.

- Constant angular velocity. The adjustment system, with its 2-channel, 256-pulse digital encoder with continous feedback, ensures a uniform and accurate weld.

- Electrode angle of incidence. The system for each weld geometry is accurate and repeatable and facilitates geometric "set-up"operations.

- Management of the welding arc. Continous monitoring of the arc current ensures constant penetration throughout the weld.

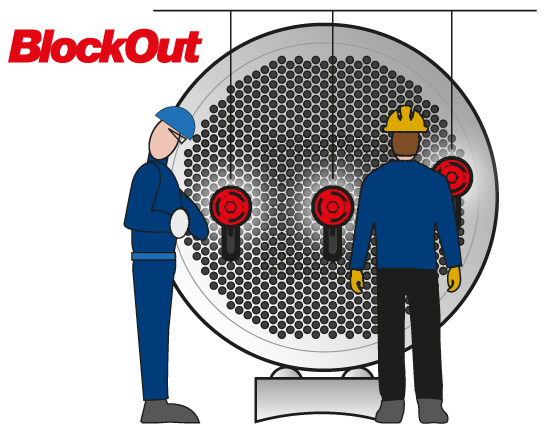

- Anti-dazzle protection. Allows multiple operators to work simultaneously on the same tube sheet without the need for personal protective equipment (PPE).

- 24/7 use. Water cooling system inside the head for significant weld improvement and guaranteed repeatability.

- For tubes from 10.0 to 51.0mm OD.

- Tangential screw electrode tightening. There is no need for service wrenches - replacement of the worn electrode is fast (meaning you no longer need to dismantle the ceramic nozzle, gas diffuser or filler wire guide).

- Wire feed unit. Fully adjustable in all directions. All manoeuvres can be performed with the single supplied key.

Transparent Protection

The movement and consumption of the filler wire is always under the operator's eye thanks to the transparent protective inspection window.

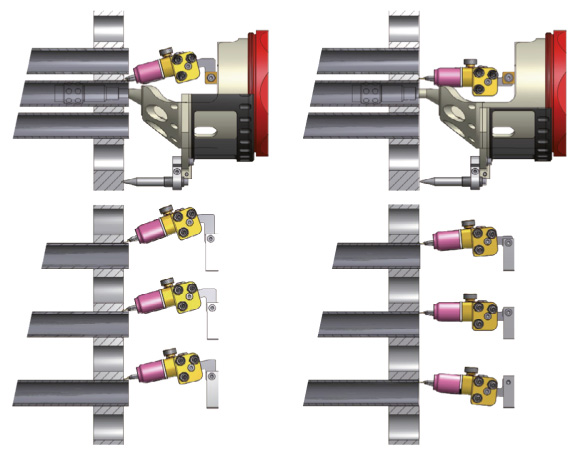

Electrode Angle of Incidence

- Thanks to the system's components which have preset angles, each welding geometry is accurate and repeatable.

- Facilitates geometric setup operations as well as being extremely stable and robust.

WTC Thrust Collar Systems

Especially for the geometry of the tube and the material to be welded.

- Special attention has been paid to the various thrust collar systems for the classical welding geometries.

- Protective inspection window for welding titanium tubes.

- All the systems we offer have the innovative Maus Italia BlockOut screens for anti-dazzle protection.

- It is now possible for multiple operators to work simultaneously on the same tube sheet without the need for personal protective equipment (PPE) which is often uncomfortable and slows down productivity.