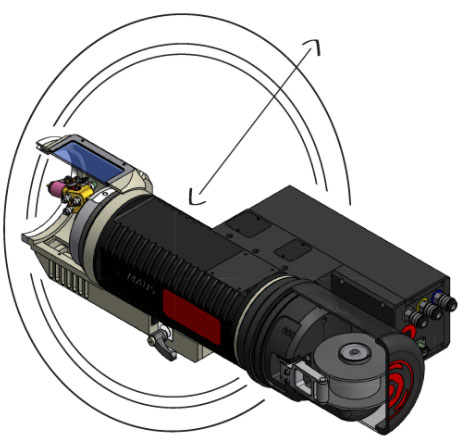

Maus MaTig-501 Automatic Welding System

Automatic positioning tube to tube sheet TIG orbital welding system.

- Allows fully automated tube to tube sheet TIG orbital welding at highly competitive costs and with a significant reduction in production times.

The MaTig-501 meets the ever increasing requirements for quality and repeatability in the execution of tube to tube sheet TIG orbital welding.

- For tube bundles with tubes from 4.0 mm to 50.8 mm (from 1/8" to 2")

- Working area: X = 1500 mm ( 59" ) / Y = 1800 mm ( 71" )

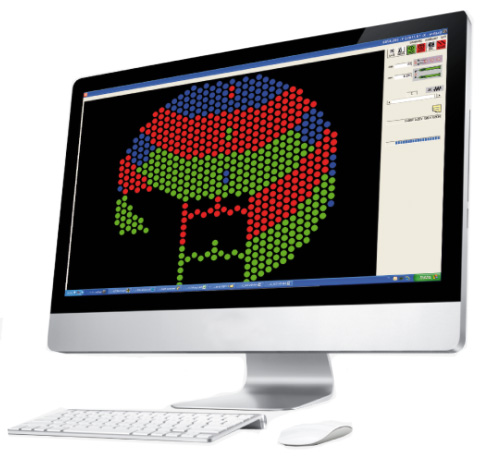

The CNC/PLC machine manufactured by Maus Italia allows the obtaining of data and statistics indispensable for handling the internal process and ability to be able to take strategic decision for company development.

Colour Graphics Interface

The programming of all the welding and positioning parameters is managed by the Windows operating system with the latest generation graphic and multi-tasking features.

Maus Italia is able to offer their customers the most advanced techniques and features of tube to tube sheet welding technology which have been developed as a result of their continuous collaboration with major heat exchanger manufacturers.

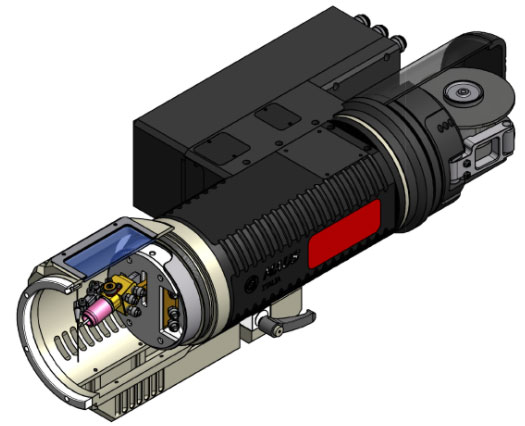

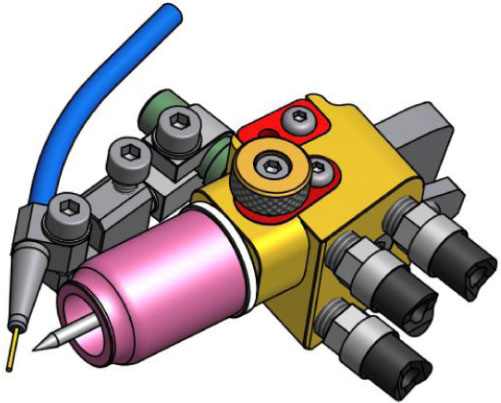

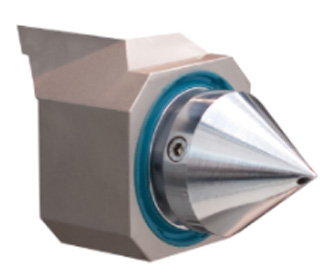

Welding Head

This new and exclusive welding head has been designed and built entirely by Maus Italia.

- Exclusive ability to adjust the welding geometry with a single key, making setting more intuitive, stable and robust.

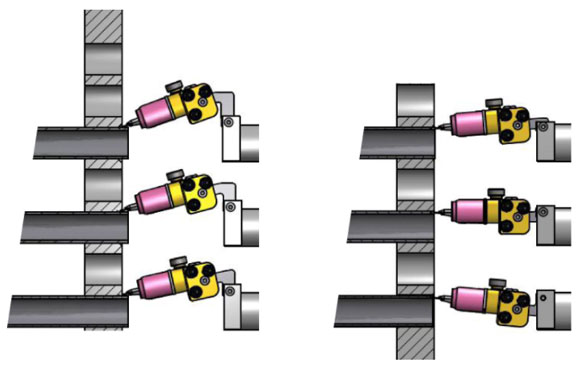

- Adaptability for welding protruding and slender tubes using an exclusive welding beam compensation system.

Internal Tube "Purging" System

The new integrated rotating purging system grant the internal protection of the tube during the welding with an extra gas line.

Fixed Angle Electrode Position Setup

The proposed system will maintain the welding geometry granting the perfect repeatability of every weld.

- Each geometry will have a dedicated angle setup easily interchangeable, really stable and solid.

Tungsten Clamping Head

The new system of the tungsten clamping allows a fast substitution of the electrode without any need of tooling and without moving the geometry of the filler wire guide, making this operation fast and precise.

Automised Management of Filler Wire

Revolutionary system of filler wire feeding, centred on the orbital axes which allows continuous and regular flow, improving the precision and distribution of the filler wire bath during the welding.

- Control the effective flow of the filler wire.

- Control of the end spool.

Automatic Radial Offset Programming - INTERPOL3

Automatisation of the radial off set for multi-pass welding: Possibility for CNC to program radius variation of the second pass without any hand-action from the operator (this will drastically improve the welding time).

- The rotation of the welding head is controlled by the CNC and it is interporable with the other axes.\

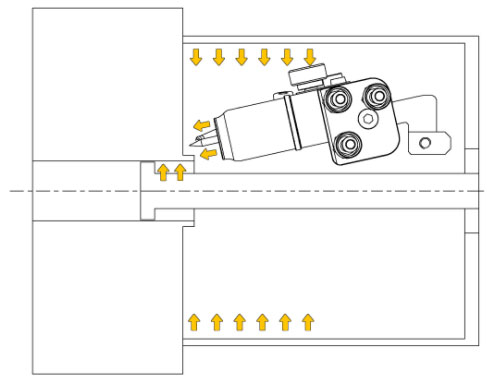

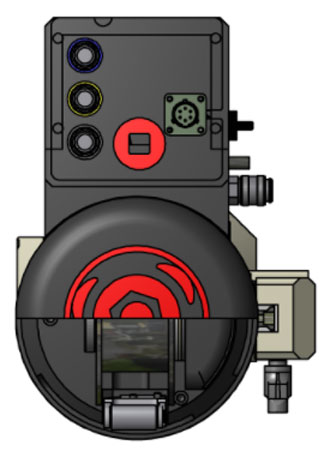

FOCS2 Centring System

The exclusive FOCS2 centring system attached to the CNC, devoid of the traditional mechanical contact accessories, already widely tested on our MA-2501 work centres, ensures the highest precision in the geometry of the welded joints.

It is a self-learning electropneumatic automatic tube centring device which is controlled by software exclusively created by Maus Italia.

- Rapid location of the workpiece zero.

- Calculation and storage of the grid position of the holes on the tubesheet.

AVC System Technology

The AVC system ( Arc Voltage Control ), based upon the principle of Ohm’s Law, automatically manages the height of the arcduring welding.

The AVC technology involves the continuous monitoring of the voltage of the voltaic arc during welding, allowing it to modulate the distance of the electrode from the weld pool.

- This results in continuous penetration across all the welding being performed.

The AVC system is standard and is used in the management of the following:

- Touch: workpiece search and electrode positioning at the required distance

- Retract: pre-determined retraction of the electrode and wire nozzle in the case of multiple passes

- Sharpening control: during formation of the weld pool, the measuring of the arc voltage allows you to check that the sharpening of the electrode is correct

- Arc voltage: an alarm can be activated should the voltage of the arc fall below a pre-determined value.

- Combined with the Interpol e allows to module the distance and the positioning of the electrode tube sheet in 3 dimension.

Third Gas Line

The MaTig-501’s exclusive welding torch allows the use of the third gas and the consequent possibility of separate management of each individual gas.

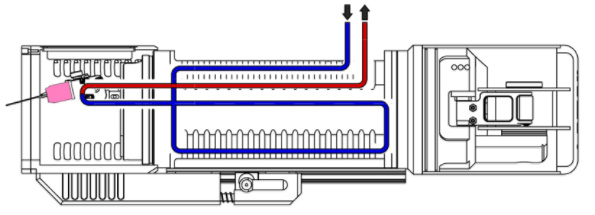

Cooling System

The MaTig-501 is equipped with a brand new water cooling system inside the torch which allows it to significantly improvement the weld performance.

- Boosted for 24/7 use.