Page 137 - SF RAIL CAT_V2.0_WEB_F2-UPDATE-02-11-18

P. 137

DERAILERS – FITTING – ALDON

DERAILERS – FITTING

DERAILERS FITTING (MADE IN USA)

HOW TO GET A GOOD DERAIL FIT

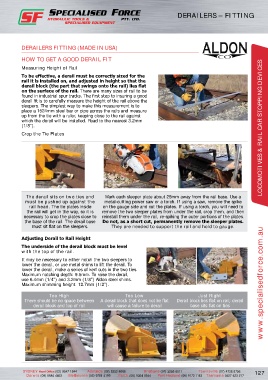

Measuring Height of Rail

To be effective, a derail must be correctly sized for the

rail it is installed on, and adjusted in height so that the

derail block (the part that swings onto the rail) lies flat

on the surface of the rail. There are many sizes of rail to be

found in industrial spur tracks. The first step to insuring a good

derail fit is to carefully measure the height of the rail above the

sleepers. The simplest way to make this measurement is to

place a 1524mm steel bar or pipe across the rails and measure

up from the tie with a ruler, keeping close to the rail against

which the derail will be installed. Read to the nearest 3.2mm

(1/8”). LOCOMOTIVES & RAIL CAR STOPPING DEVICES

Crop the Tie Plates

The derail sits on two ties and Mark each sleeper plate about 25mm away from the rail base. Use a

must be pushed up against the metal-cutting power saw or a torch. If using a saw, remove the spike

rail head. The tie plates inside on the gauge side and cut the plates. If using a torch, you will need to

the rail will get in the way, so it is remove the two sleeper plates from under the rail, crop them, and then

necessary to crop the plates close to reinstall them under the rail, re-spiking the outer portions of the plates.

the base of the rail. The derail base Do not, as a short cut, permanently remove the sleeper plates.

must sit flat on the sleepers. They are needed to support the rail and hold to gauge.

Adjusting Derail to Rail Height

The underside of the derail block must be level

with the top of the rail.

It may be necessary to either notch the two sleepers to

lower the derail, or use metal shims to lift the derail. To

lower the derail, make a series of kerf cuts in the two ties.

Maximum notching depth: 9.5mm. To raise the derail,

use 6.4mm (1/4”) and 3.2mm (1/8”) Aldon steel shims.

Maximum shimming height: 12.7mm (1/2”). www.specialisedforce.com.au

Too High Too Low Just Right

There should be no space between A derail block that does not lie flat Derail block lies flat on rail; derail

derail block and top of rail will cause a failure to derail base sits flat on ties

SYDNEY Head Office (02) 9547 1844 Adelaide (08) 8352 8866 Brisbane (07) 3256 6011 Townsville (07) 4728 8756 127

Darwin (08) 8984 4453 Melbourne (03) 9761 4199 Perth (08) 9354 8544 Port Hedland (08) 9172 1113 Tasmania 0427 423 217